Chapel Hill, North Carolina USA

Expert Rheology Characterization and Material Testing Services

Deliverables

Scientific Rigor & Experience

Collaboration & Responsiveness

Flexibility with Rapid Turnaround

Detailed Report

No Bureaucratic Hurdles

Cost Effective Support for Small & Large Projects

Rheology Applications

Research & Development

Formulation & Process Optimization

Batch Consistency & Stability

Sensory Properties

Manufacturing (QbB, Quality by Design)

In-Process and Quality Control

Prove/Disprove Equivalence for Regulatory & IP (Q3)

"We should have reached out to RTS earlier in the R&D process to better rheologically understand our product and the impact of manufacturing conditions, especially before locking down specifications." Comments like this have been mentioned by RTS clients more than a few times. Performing either a single assay to address a specific technical need or an array of assays to generate a comprehensive rheological profile, is often a very small and highly efficient investment with a potentially large return.

RTS provides a broad range of rheological assay options with flexibility, no bureaucracy and rapid turnaround for clients ranging from academic, start-up to international conglomerate. In contrast to the large "all-in-one" Contract Research Organizations (CRO) and Contract Development and Manufacturing Organizations (CDMO), RTS is focused on rheology. RTS clients particularly appreciate the highly responsive and personalized interactions along with real-time flexibility and technical experience for methodical and strategic investigations, especially for the "we're not sure what's going on" and "Houston we have a problem" situations (see "Testimonials" below).

Not sure what assays and parameters would be most appropriate to address the question you seek to answer?

No problem - RTS will provide guidance.

Although the various assays are individually described below and under the "Assays Performed" tab above, it may be helpful keep in mind that Rheology Testing Services specializes in "one-off" special assays tailored and applied to meet client needs. In addition, multiple assays can be seamlessly coupled as a single automated sequence in various interesting and informative ways to quantitatively model rheological properties during multiple processing stages. These stages often involve different shear stresses, shear rates and thixotropic rebuilding during mixing and pumping, along with varying heating and cooling cycles and hold times. For example, bracketing frequency sweeps can be performed before and after a yield stress, thixotropy study, or temperature sweep to further probe how the sample may have rheologically (ir)reversibly changed.

OFTEN REQUESTED ASSAYS

Additional assays listed under "Assays Performed" tab (page top)

Viscosity with

Shear Rate Ramp

Viscosity (resistance to flow) is just one component of a detailed rheological profile to understand material response to various conditions.

Viscosity can be quantified with several methods. A frequently requested assay is the rotational shear rate ramp applied across a wide range of conditions. The figure below shows honey, a Newtonian fluid does not appreciably shear thin with increasing shear rate; whereas, mayonnaise (non-Newtonian) does shear thin.

Typically, these assays are helpful to generate flow curves, often showing shear thinning to efficiently model processes and applications.

Yield Stress with

Shear Stress Ramp

Yield stress is often determined by a shear stress ramp assay to quantify the rheological "breakpoint" that leads to flow.

For example, honey readily spreads (flows) with a much lower yield stress & yield viscosity than peanut butter which requires much more effort (stress). The figure below compares 2 ketchup brands that initially undergo elastic deformation with increasing stress, followed by flow (sharp viscosity decrease) that is quantified with both yield stress and yield viscosity.

Yield stress determinations are helpful to model pumpability, spreading, delivery, sedimentation potential (Stokes' Law) and feel.

LVER & Stability with

Amplitude Sweep

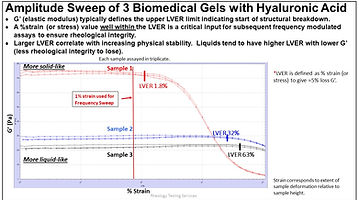

An amplitude sweep is a routine oscillatory assay during which amplitude (deformation energy input as either strain or stress) increases over time and frequency is held constant.

During this assay, the sample is increasingly deformed during back & forth oscillations to determine its rheological breakpoint (LVER; Linear Viscoelastic Region) that correlates with rheological stability. for example, gelatin wiggled beyond its LVER falls apart. As described in the next panel, knowing the temperature dependent LVER is important to determine the experimental strain or stress input for often requested subsequent frequency modulated assays.

The figure below shows typical amplitude sweep output as G' (elastic modulus; solid-nature) with increasing % strain to determine LVER for 3 very different gels containing hyaluronic acid. Among similar samples, larger LVER values correlate with increasing physical stability. As shown below, more liquid-like materials tend to have higher LVER with lower G’ (less rheological integrity to lose). Other outputs such as phase angle and tan delta can further quantify liquid- vs solid-like properties.

Viscoelasticity with

Frequency Sweep

A frequency sweep is another routine oscillatory assay during which amplitude (either strain or stress) is held constant and frequency changes over time. In addition to many applications, this assay is helpful to quantify viscoelastic properties for semisolids that are not amenable to rotational assays. The typical measurables for frequency sweep assay is stiffness (G*; complex modulus), solid nature (G'; elastic or storage modulus), liquid nature (G"; viscous or loss modulus), degree of fluidity (phase angle), complex viscosity and tan delta (G"/G').

To properly perform frequency sweep, it is important to use a strain or stress input within its LVER determined from amplitude sweep described in the previous panel. This ensures the sample's rheological integrity is maintained during the assay and hence validity of the results.

Silly Putty is an excellent example of changing viscoelastic properties with frequency. When near at rest (low frequency), it slowly spreads like a liquid (G">G'). However, when rolled into a ball and dropped on a table (high frequency on impact), it bounces like a solid (G'>G"). Check out "Learn More" below to see actual plot.

TESTIMONIALS

Chapel Hill, North Carolina USA

©2017 by Rheology Testing Services. Proudly created with Wix.com